The most common question often faced by dairy professionals is ” How to make silage for cows”. In this article, we will discuss in detail about silage making.

Silage is a preserved form of green fodder. Fodder is preserved in air-tight conditions to maintain its nutritional value, improve taste and quality and make it more easily digestible. Green fodder is preserved under anaerobic conditions at low pH during silage making. Lactic acid is produced during the fermentation that contributes to lowering the pH. Silage is also called a “pickle of fodder”. During silage making, green fodder is fermented through the presence of anaerobic bacteria.

Advantages of Silage Making

- Availability of fodder at the time of shortage or feed scarcity.

- Early availability of land for the next crop as the whole fodder is harvested at once.

- Expenditure on working labor is minimum than during normal forage cutting & usage.

- It is more economical than other traditional feedings.

- Silage is more palatable, digestible, and nutritious.

- Less desirable parts of plants (stems) can also be used as silage for consumption.

- It allows the usage of many byproducts as feed sources.

Steps for Silage Making

- Selection of Fodder (Checking the vegetative nature or moisture of standing fodder)

- Harvesting the fodder

- Chopping

- Storage & baling

Selection of Fodder

Fodder with an adequate amount of carbohydrates and a moisture level of more than 65% should be selected. Commonly corn, sorghum, oat, and millet are used for silage making. Corn is considered standard fodder for silage making because it has an adequate amount of carbohydrates that are required for bacterial fermentation. In this article, we will be focusing on corn silage. Leguminous fodder crops can also be used but they lack the required amount of carbohydrates. Molasses or external carbohydrates are sprinkled on such crops during silage-making.

Harvesting the Fodder

Fodder should be harvested when it has a 65-70% moisture level and maximum nutrients or energy. Corn should be harvested when it reaches the given level.

- Corn should be harvested before the leaves start turning yellow-brown and dry.

- It should be harvested when the ear or kernel is well-dented.

- At the time of harvesting, the moisture level should be 32-35 % in grain.

- There should be a 50% milk line (kernel) in corn grains.

- When the color of corn leaves starts to change to light green.

Chopping the Fodder

Fodder should be chopped in the size of 1-3 cm or 0.5-1 inch. Modern choppers are available for this chopping process, which makes the process rapid and results in the improvement of silage quality. Chopping size depends upon the dry matter of the fodder. Too short chopping of crops with low dry matter will result in effluent nutrient losses. While short chopping of fodder with high dry matter will be helpful for the bacteria to get more exposure for fermentation and produce good-quality silage.

Storage & Bailing

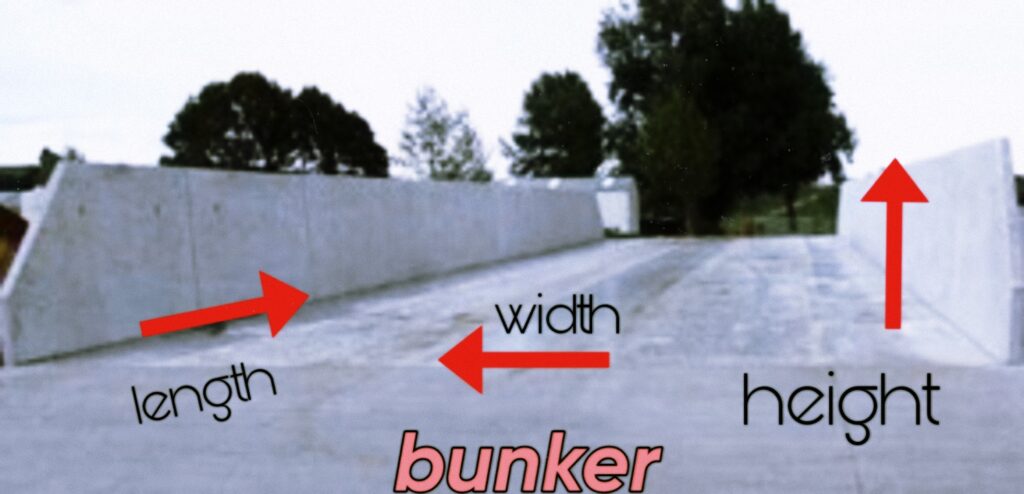

The chopped fodder should be stored and pressed as soon as possible. Chopped fodder can be stored in silage bags, pits, and bunkers. The best way is to build a bunker and minimize the loss of fodder. Following instructions should be kept in mind while selecting the storage place.

- The bunker should be near the animal shed

- Avoid the presence of salinity in the bunker

- The bunker should be in a higher place to protect it from rainwater.

The whole process of harvesting, chopping, pressing, and storing should be completed within 16 hours. Spread the fodder in 6-7 inches layers and press the layers with the moving tractor. This helps to squeeze out the air between the chopped particles and start the fermentation process rapidly. At this stage, you can also use different additives to stimulate microbial activity for fermentation. Use a waterproof plastic sheet or cover on the bunker and place heavy objects like vehicle tires or sandbags on it. Silage will be ready for the consumption of animals in 4-6 weeks.

Precautions during storing

- Chopp the fodder in standard small size.

- Protect the fodder from dirt, and check the tires of tractors before pressing.

- Pack the fodder appropriately and protect it from rainwater and air.

- Storing process should be quick to avoid the increase in temperature of silage.

Silage is a preserved form of green fodder. Fodder is preserved in air-tight conditions to maintain its nutritional value, improve taste and quality and make it more easily digestible. Green fodder is kept under anaerobic conditions at low pH during silage making.

A silo is a place or container used to store or preserve green fodder for silage-making. For example silo towers, trench silos, etc

There should be strong walls with thicknesses of 18-27 inches on three sides of the bunker. The base floor should be concrete made and with a gradual slope. The length and the width of the bunker depend upon your requirement.